ABOUT HAKUTA

The industrial trading and service company HAKUTA Industrial Equipment Joint Stock Company provides a wide range of professional and comprehensive metal processing equipment, solutions, and technology, as well as accessories and consumables, to the shipbuilding, mechanical, automotive, steel, steel structures, tanks and pipelines, petrochemical, and other industries.

With many years of expertise, we are pleased to be among the top providers of industrial equipment in Vietnam, valued by both local and international partners and clients. Products sold by HAKUTA are of exceptional quality and guaranteed to be of their original origin.

HAKUTA: COMPLETE SOLUTIONS, SKILLED SERVICES.

Access by “Application”

TANKS – PIPELINES

STEEL STRUCTURE

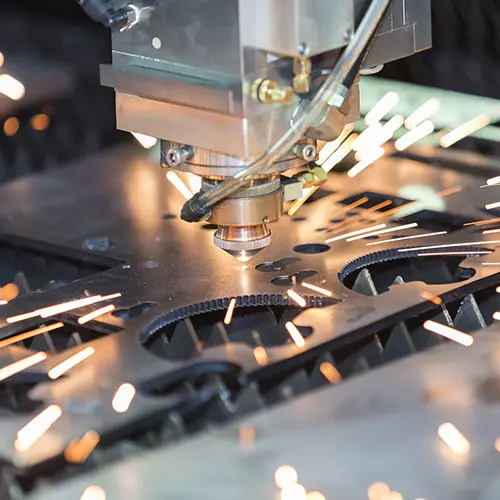

SHEET METAL PROCESSING

EXACT MECHANICS

ACCESSARY

SERVICE

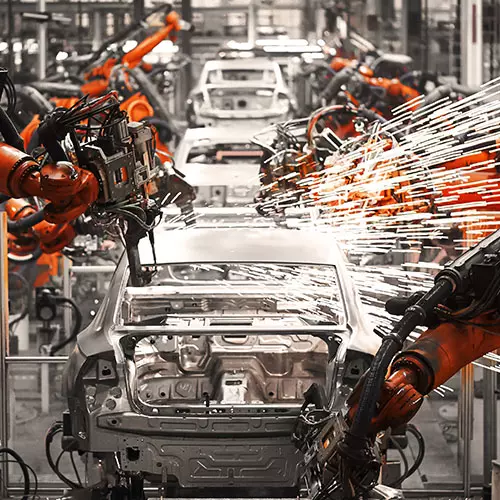

AUTOMOBILE INDUSTRY

SHIPPING INDUSTRY

PETROCHEMICAL

PRESSURE – HEAT EXCHANGE

ENERGY